Replacing Rear Arm Bearings

Replacing rear arm bearings

Hi All,

Managed to get one from Pleiades.

Regards to all

Scott

Managed to get one from Pleiades.

Regards to all

Scott

Scott Blackman, BX19TXD Break, JAGUAR XJS V12

Cracked into the rear arm bearings this arvo while waiting for parts from the stealer.

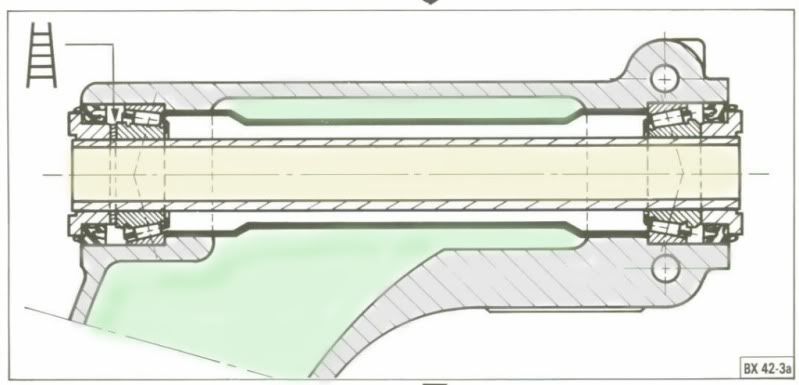

Got the arm into the vice and removed the rusty debris and the plastic tube then the guide says 'knock off the bearing outer ring'

As I've never seen the inside of an arm before, I don't know what this is meant to look like. Are there any photos anywhere that someone could post or link to this 'sticky' please?

If you look at the arm from the outside, right near the top is a 1 or 2mm flat ring which has rubbery remains either side of it. Does this stay or is this the remains of the bearing outer ring?

Thankyou

Got the arm into the vice and removed the rusty debris and the plastic tube then the guide says 'knock off the bearing outer ring'

As I've never seen the inside of an arm before, I don't know what this is meant to look like. Are there any photos anywhere that someone could post or link to this 'sticky' please?

If you look at the arm from the outside, right near the top is a 1 or 2mm flat ring which has rubbery remains either side of it. Does this stay or is this the remains of the bearing outer ring?

Thankyou

Todd

this yellow writing is really hard to read

this yellow writing is really hard to read

-

Linegeist

- BXpert

- Posts: 788

- Joined: Thu Oct 27, 2005 6:35 pm

- Location: Anglesey - out near the nuke power station!

Hi Todd.

That'll be the oil/grease seal. There's one at each end. Prise that out carefully with a screwdriver (they're fairly soft metal) and the next ring behind that will be the outer bearing track.

The problem you may have is getting something to hit on the almost flush-fitting bearing ring. I ran a bead of weld around the thing with my MIG welder - this both heated up the ring thus breaking any adhesions, and the ridge of new metal then gave me a thwacking point.

Hals und Bein bruch!

That'll be the oil/grease seal. There's one at each end. Prise that out carefully with a screwdriver (they're fairly soft metal) and the next ring behind that will be the outer bearing track.

The problem you may have is getting something to hit on the almost flush-fitting bearing ring. I ran a bead of weld around the thing with my MIG welder - this both heated up the ring thus breaking any adhesions, and the ridge of new metal then gave me a thwacking point.

Hals und Bein bruch!

Hi Todd,toddao wrote:.................

Are there any photos anywhere that someone could post or link to this 'sticky' please?

If you look at the arm from the outside, right near the top is a 1 or 2mm flat ring which has rubbery remains either side of it. Does this stay or is this the remains of the bearing outer ring?

Thankyou

This LINK should reveal all to the /\ finding's, " the 1 or 2mm flat ring" as you describe it, is a seal (item #11 in the the first post of this thread) which will need replacing and should come with a full repair kit.

I hope this is of help !

- mat_fenwick

- Moderator

- Posts: 7327

- Joined: Tue Sep 20, 2005 4:08 pm

- Location: North Wales

- x 20

...and also shrinks the ring as the weld bead cools, making removal a lot easier!Linegeist wrote:I ran a bead of weld around the thing with my MIG welder - this both heated up the ring thus breaking any adhesions, and the ridge of new metal then gave me a thwacking point.

I'm reminded of the time I helped my father in law change the head bearings on his bike - I managed to get the old races out by welding them and left him to tap the new ones into position. I suggested using the old bearing races as a drift, as they would be an appropriate size...

I came back to find he'd picked up the bearing cages, complete with rollers and had hammered these into the pristine bearing surfaces of the new races!

If you do use the old bearing races to press the new ones into the arms, grind a little off the outside to prevent them sticking as you drive them in. If you really want to go to town on it you could soften them slightly (to make sure they can't mark the new ones) by tempering them in the oven at 200°C+ for an hour, but them depends on your other half's level of tolerance...I've never bothered/dared.

-

Defender110

- Over 2k

- Posts: 5918

- Joined: Wed Dec 16, 2009 8:02 pm

- Location: Harwood, Bolton

- My Cars: Land Rover Discovery Series 1 200tdi 3 door

Land Rover Discovery Series 2 Facelift TD5

2020 Fiat Panda cross 4x4 twin air. - x 27

As a disguise you could line them with pastry and fill with steak and kidney for his and hers individual piesmat_fenwick wrote: If you really want to go to town on it you could soften them slightly (to make sure they can't mark the new ones) by tempering them in the oven at 200°C+ for an hour, but them depends on your other half's level of tolerance...I've never bothered/dared.

Kevan

1997 Mercedes C230 W202

2003 Land Rover Discovery Series 2 Facelift TD5 - Daily driver / hobby days and camping.

1993 Land Rover Discovery 200tdi Series 1 3 door - in need of TLC

2020 Fiat Panda 4x4 Cross Twin Air.

1997 Mercedes C230 W202

2003 Land Rover Discovery Series 2 Facelift TD5 - Daily driver / hobby days and camping.

1993 Land Rover Discovery 200tdi Series 1 3 door - in need of TLC

2020 Fiat Panda 4x4 Cross Twin Air.

Thanks guys for all the replies. I shall proceed tomorrow and report back. I just didn't want to damage something that was irreversible.

Bob, hopefully I won't 'break my neck and legs' (German expression for good luck!!) unless the arm falls out of the vice while I'm lying under it

Cheers everyone!

Bob, hopefully I won't 'break my neck and legs' (German expression for good luck!!) unless the arm falls out of the vice while I'm lying under it

Cheers everyone!

Todd

this yellow writing is really hard to read

this yellow writing is really hard to read

Ok, the latest.. it seems that the bearings were never changed since 1985 and 130,000 miles so they are practically integrated into the arms with rust.

I need to know what the tolerance is, whether I can proceed with these arms or must look for other better ones? Firstly I can't see these bearing rings ever moving and secondly there is the 'egg shaped' damage as described previously by Bob from corrosion/wear in the linings.

I've got a Mig set up but it's got some problems - runs off 380v ( which is available from the next building) but keeps tripping the electricty.

I need to know what the tolerance is, whether I can proceed with these arms or must look for other better ones? Firstly I can't see these bearing rings ever moving and secondly there is the 'egg shaped' damage as described previously by Bob from corrosion/wear in the linings.

I've got a Mig set up but it's got some problems - runs off 380v ( which is available from the next building) but keeps tripping the electricty.

Todd

this yellow writing is really hard to read

this yellow writing is really hard to read

- mat_fenwick

- Moderator

- Posts: 7327

- Joined: Tue Sep 20, 2005 4:08 pm

- Location: North Wales

- x 20

I take it you don't have arms on the new subframe?

The usual area to become egg shaped is (in my limited experience) the sealing surface (as the bearings break up and wear away the softer steel of the arm itself). So it can be reasonably well 'fixed' with sealant, depending on the level of damage. I've not seen any where the area the bearing race sits on has been damaged, and if it has any repair would need to be machined back with a high level of accuracy for the new race to fit securely. Any chance of photos to assess?

If you can get the welder working it WILL make it a lot easier to get the old bearing races out... Do you know what is tripping, i.e. an overload trip or an earth leakage (RCD) trip? If the latter and the welder hasn't been used for a while it could just be damp causing enough of an earth leakage to trip things out.

The usual area to become egg shaped is (in my limited experience) the sealing surface (as the bearings break up and wear away the softer steel of the arm itself). So it can be reasonably well 'fixed' with sealant, depending on the level of damage. I've not seen any where the area the bearing race sits on has been damaged, and if it has any repair would need to be machined back with a high level of accuracy for the new race to fit securely. Any chance of photos to assess?

If you can get the welder working it WILL make it a lot easier to get the old bearing races out... Do you know what is tripping, i.e. an overload trip or an earth leakage (RCD) trip? If the latter and the welder hasn't been used for a while it could just be damp causing enough of an earth leakage to trip things out.

Mat, I thought there were arms on the new subframe but no - I already thought : no problem I'll swap in the new ones. But I was deceived - it is only the subframe. I had moved so much 'crap' in one hit from that parts cache into the barn I had forgotten the details!

The second arm is even worse than the other, if that's possible. As for the welder, not only does it have an enormous extension lead to contend with ( bringing the power from the next building) but it could be damp. I don't know enough about electricity really. It switches the power off at the consumer unit. I was hoping it was just the fuses were rated too low.

It comes on and feeds the wire then the minute it makes contact it trips out! I will speak to a 'sparks' friend today hopefully..

No such thing as a 'quick' job!

The second arm is even worse than the other, if that's possible. As for the welder, not only does it have an enormous extension lead to contend with ( bringing the power from the next building) but it could be damp. I don't know enough about electricity really. It switches the power off at the consumer unit. I was hoping it was just the fuses were rated too low.

It comes on and feeds the wire then the minute it makes contact it trips out! I will speak to a 'sparks' friend today hopefully..

No such thing as a 'quick' job!

Todd

this yellow writing is really hard to read

this yellow writing is really hard to read

The old bearing rings are out!!

I borrowed a gas fuelled weed burner machine to heat up the old rings in the arms. Then I fabricated a drift from old water pipe as recommended by that excellent Japanese site but I put a taper on it with the bench grinder to get better 'bite' on the tiny amounts of ring projecting. Another innovation was putting a steel bar up through the bottom of the drift and leaning on it to 'lock' the drift onto the ring so I could give it a good whacking without it jumping out.

Cleaned all the old rings, sprayed rust loosener. Whacked and whacked, then heated and repeated. I had to constantly grind the water pipe drift to keep it true but then the first one came out and so on..

Two of them hardly had anything left and shattered into pieces.

I'm well chuffed. Hopefully get the new bearings in this arvo.

I borrowed a gas fuelled weed burner machine to heat up the old rings in the arms. Then I fabricated a drift from old water pipe as recommended by that excellent Japanese site but I put a taper on it with the bench grinder to get better 'bite' on the tiny amounts of ring projecting. Another innovation was putting a steel bar up through the bottom of the drift and leaning on it to 'lock' the drift onto the ring so I could give it a good whacking without it jumping out.

Cleaned all the old rings, sprayed rust loosener. Whacked and whacked, then heated and repeated. I had to constantly grind the water pipe drift to keep it true but then the first one came out and so on..

Two of them hardly had anything left and shattered into pieces.

I'm well chuffed. Hopefully get the new bearings in this arvo.

Todd

this yellow writing is really hard to read

this yellow writing is really hard to read

- mat_fenwick

- Moderator

- Posts: 7327

- Joined: Tue Sep 20, 2005 4:08 pm

- Location: North Wales

- x 20

As per request, links to a couple of picture sets on removing/re-bearing BX rear arms:

http://www.rmattila.com/images/remontit ... a_irrotus/

http://www.rmattila.com/images/remontit ... akerointi/

Best Regards,

-Riku

http://www.rmattila.com/images/remontit ... a_irrotus/

http://www.rmattila.com/images/remontit ... akerointi/

Best Regards,

-Riku

Speechless quad lying flat on his bed, communicating by moving eyes.

BX Van 1.9D -90 Gone.

BX Van 16S -90 For sale.

BX Van 1.9D -90 (Earned!) Gone.

BX Break 1.9D -90 (officially a "5 seat van" since 2005) Waiting to be towed to a new home.

BX Van 1.9D -90 Gone.

BX Van 16S -90 For sale.

BX Van 1.9D -90 (Earned!) Gone.

BX Break 1.9D -90 (officially a "5 seat van" since 2005) Waiting to be towed to a new home.