Dunno if you are like me, but nothing attracts me more than totally pointless challenges. Particularly if I've got plenty of other highly useful things to do. I've got a brand new pump on my only BX, so what the hell would I want to be opening the old one up for ?

Well, because it's there, and I've never opened it up before...

As it happens, it's surprisingly easy, and I wish I had tried before shelling out on the new pump.

First off, you need a special extractor tool to get the pulley off.

I used an Aldi fake Dremel, an old jack and two lengths of mild steel bar to make mine :

Into a big vice, and wind away !

The pulley came off with surprising ease :

Next up, following the mad Frenchman's method, I tried whacking the shaft with a big hammer to get the cover off : bad idea. It fattens the end of the shaft, which then sticks in the roller bearing. I would strongly advise making a second extractor tool to get a grip on the casing. In my case, the first tool was luckily easily adaptable :

So out comes the shaft. Be careful not to loose the small bits inside the pistons if they should fall out. Then you might want to get the ball-bearing out, you'll need a drift for this, about 18mm diameter :

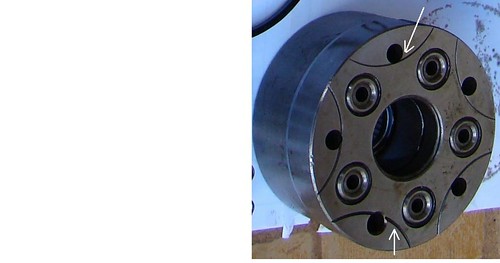

Then, to separate the two machined blocks, there are 5 5mm allen screws :

Which gives you this :

Here you can see the wear on the bottom side of the valve disc :

This is what you find inside the pistons :

And here is an overall view of the innards :

The only thing I didn't bother taking out was the needle bearing, it would be simple to drift out :

If your pump is leaking at the pulley end, this is probably the cause :

an o-ring roughly ID 25mm OD 32mm. It would probably be possible to find a replacement.

The big case joint might be more difficult to replace. Silicone might be an answer (it's on the low pressure side of the pump), or at worst, maybe welding the case to the body ?

Conclusion, it is most definitely possible to convert an HP pump from a low-mileage non-PAS petrol-engined car for use in a high-mileage PAS diesel car.

It might even be possible to recondition worn pumps by flipping over the valve discs, any volunteers