I had bought a Volvo 240 high level brake light for the BX, something I was going to make brackets and whatnot for. Then while shopping for something unrelated I had the sort of high level brake light I actually wanted to fit pop up in my suggestions. The algorithm worked! So today, I'm going to show you how I fitted this without a soldering iron and with the help of a C clamp.

The first task is the scary bit, I had to remove the inner C pillar trim to check the wiring route I wanted to take was viable. There is wiring that runs into the tailgate for the central locking, so that gave me access from the tailgate into the car so that's the route I chose to take since it should be the most straightforward. First job is to remove the two small screws holding the top of the C pillar trim in place and then gently prise each of the fir tree studs out of the holes to get the C pillar trim off. I did not enjoy this part of the job one bit. You also need to be aware there's a plastic hook on the point at the back of the car, you don't want to be snapping that off.

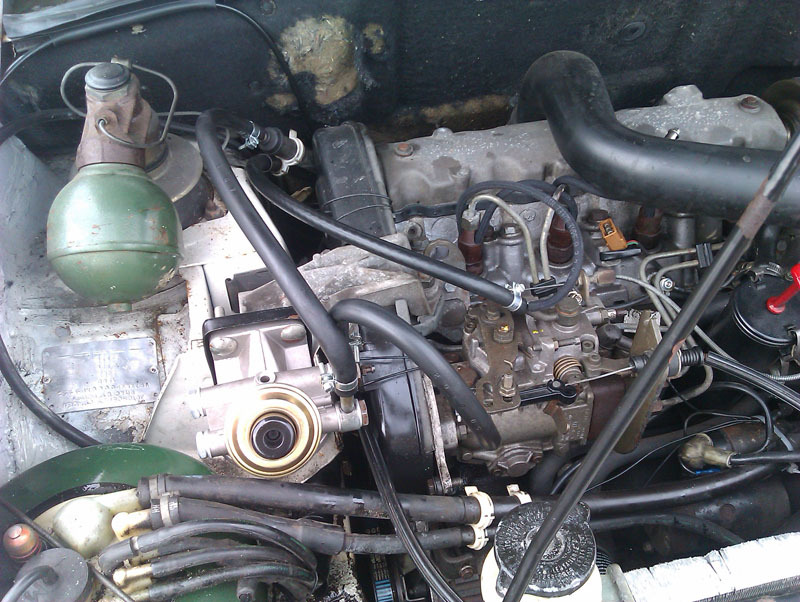

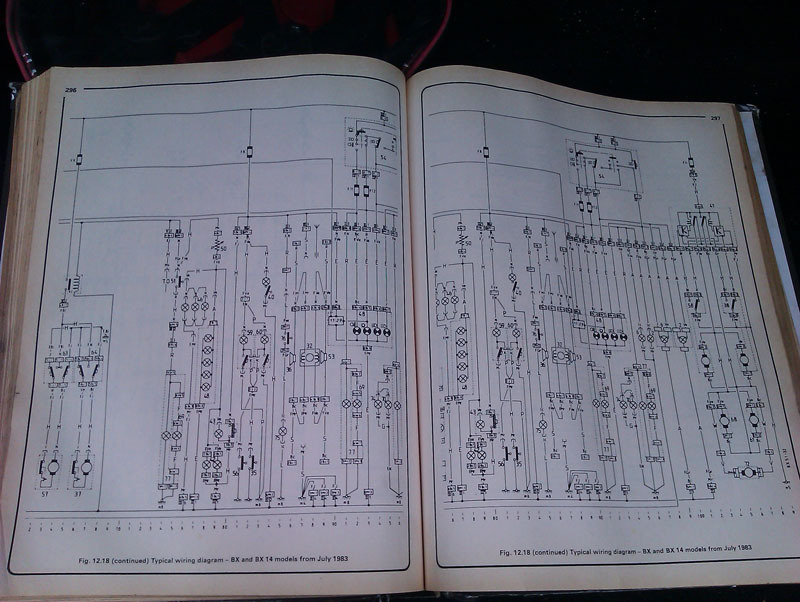

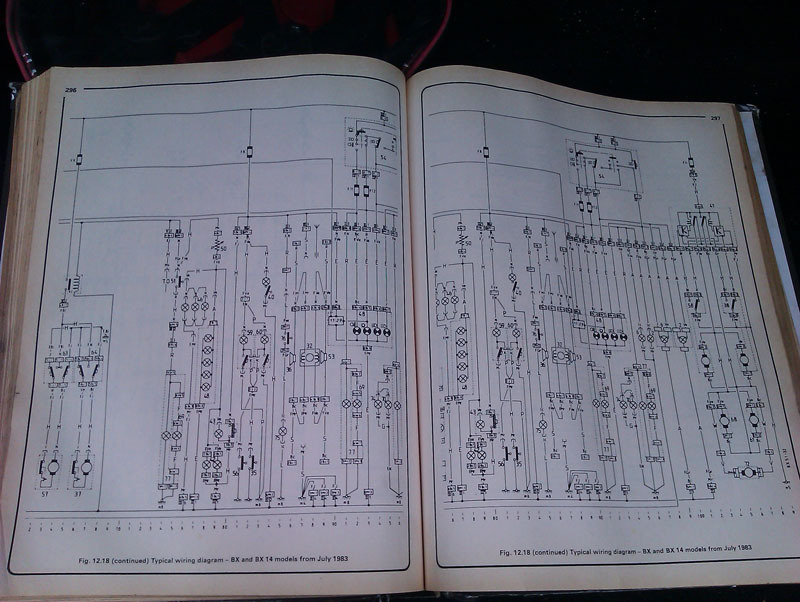

That done, it confirmed the wiring route I wanted to take could be taken quite easily, didn't even have to drop the headlining, just ease the very corner out so I could see when the wire had been fed through. Before committing to anything, I then took a look at what the book suggested was the wiring diagram so I could determine which was the wire I need to splice into...

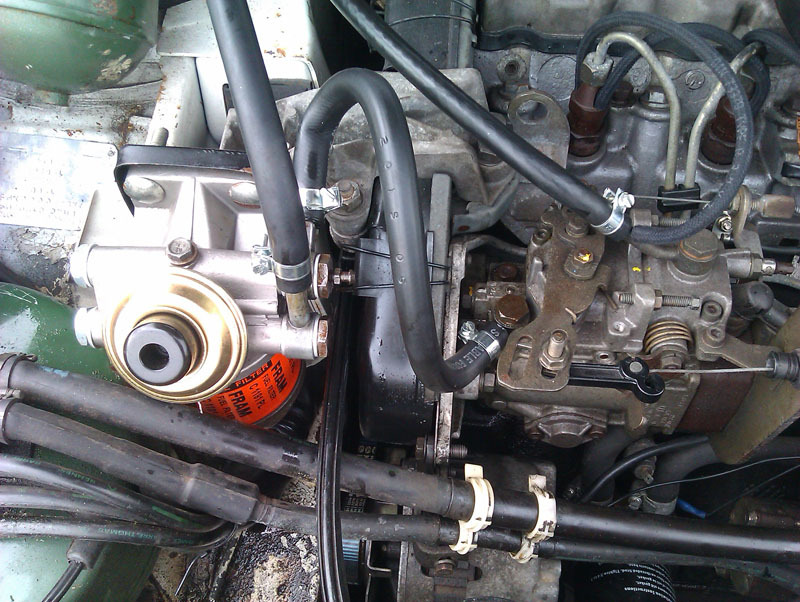

er... NOPE. I couldn't figure out how any of this, or any of the other wiring diagrams, related to what I saw on the car so instead I chose the practical approach. Built into the back of the light clusters is sort of a printed circuit board, only it's made out of a sheet of metal, that's held in place by melted bits of plastic. Looking at this I could understand which sections of it powered the brake and running lights and that it correlated to the brown plug on the back of the light cluster. The green plug is the piggy-back for the other light cluster, and the small yellow plug deals with the indicators. What I didn't know is which of the pins on the brown plug related to the brake light and I didn't know where my multimeter was (typically I found it when I was putting tools away after this job was done), so I went the practical approach. I stuck the wires from the new brake into the slots for the pins on the brown plug until I got a pair that lit the brake light up. I have no idea if this is good practice, but it seemed low risk as the worst I could theoretically do I assumed was to blow a bulb or a fuse. After a bit of trial and error, the only pins that operated the brakes were these.

Then I had to figure out the best way to connect the new and old wiring. After a bit of jiggery pokery, I figured out that you can prise the black part of the plug out which gives you access to the back of the pins. The factory wiring just pushes into these pins to make a connection so, in theory, it made sense for me to do the same and stack the new wires on the old ones. A little nerve wracking prising the plug apart since I had nothing to replace it with, I found the best way was to prise it up with a screwdriver from each narrow side and then push the locking tabs in as you go, eventually it pops out. Then fiddle about with the new wire and test several times to make sure you had a good connection before putting the black insert back in. I did have to resort to a tool not commonly found in an electrician's kit which was a small C clamp so that I could press the black insert home, using pliers or similar got one side in and not the other, so this worked quite well.

More testing after that and the light was still working reliably. Good. Next was to tidy away the wiring. I didn't have the sort of clips I wanted for the one short bit of exposed wiring at the top of the tailgate, so I improvised with a clip I did have that was just bit enough. Eventually I'll replace this with some more suitable edge clips.

The extra wire was tidied away and given a cable tie so it didn't end up hanging down outside the trim.

I carefully reinstalled the trim I'd disturbed and the wire was mostly invisible, quite a satisfactory job. Further testing showed that the light was still working. There's no trim to hide the wire behind in the side pockets in the boot, what you see in there is literally the bodywork of the car. Fortunately there's a trim bracket you can hook the wire over to keep it close to the back of the light cluster so unless you go looking for it, you don't see the wire.

I'd already figured out any rear visibility issues, as in what it blocked from inside the car and where it was most visible from the outside of the car, which is why I settled on having it at the top of the screen instead of at the bottom. I did double-check this before instalation since there was enough wire to put the light at the bottom of the screen, it just didn't work as well there.

It's an unobtrusive bit of kit that gives me a little more peace of mind since I now have a brake light at eye level for other drivers. I like that it's not very obvious inside, or outside, of the car. Oh, and I suppose I should show it lit just to prove it does work. A little difficult to see in the daytime with the tailgate open, at night I'm sure it'll be much more obvious.