The End of Everything

-

SamWise

- BXpert

- Posts: 159

- Joined: Wed Jan 16, 2008 9:48 am

Oh don't worry - I have the urge to murder cyclists too. Probably less than 50% of them where I live, but more than 50% in London or Cambridge. One particular morning I was on the Embankment heading into East London, and overtook this fellah creaking along on a rusty mountain bike. I was riding an old Raleigh 20 folding bike from the 70's, (cos I couldn't afford a fancy folder at that point and needed a bike to take on the train), but I'm fast when I'm in shape, and can keep up with the guys on the carbon fibre road bikes even on something like that. I and the rest of the Embankment Peloton stopped at the next red light, and this guy just creaked through the middle of us, shot across the junction, swerving around cars that were turning right, and carried on. Of course, he was still slow and creaky, so I had to pass him again, necessitating my diving out into the traffic. This happened at every set of lights (5 or 6 times), and by the end, I wanted nothing so much as to stick my pump through his spokes. You'll be pleased to hear I'm a very law abiding cyclist - only on the road, obey all the signs and signals. The only thing I do that can piss some people off is that I'll overtake slow moving traffic. Some drivers hate that, but tough luck, I do it safely, and that's what a bike is for!

1966 Triumph Herald convertible with big valve twin carb Spitfire head

1973 Bedford Panorama Elite II Bus

1994 2.1TD Citroen XM

1992 Citroen AX Echo 1.4D

1973 Bedford Panorama Elite II Bus

1994 2.1TD Citroen XM

1992 Citroen AX Echo 1.4D

-

docchevron

- The Immoderate half of the admin team

- Posts: 7524

- Joined: Sun Jun 04, 2006 7:03 pm

- Location: A Bucket of Fish

- x 7

I have no problem at all about being overtaken by anything, it's when they undertake I get narked.SamWise wrote: The only thing I do that can piss some people off is that I'll overtake slow moving traffic. Some drivers hate that, but tough luck, I do it safely, and that's what a bike is for!

Especially whe I'm turning left, in a 40foot motor, and some arsehole on a bike (and it's been motorbikes aswell) some steaming up the inside.

I really would kill all of them.

Smokes lots, because enough's enough already!

Far too many BX's, a bus, an ambulance a few trucks, not enough time and never enough cash...

Far too many BX's, a bus, an ambulance a few trucks, not enough time and never enough cash...

-

SamWise

- BXpert

- Posts: 159

- Joined: Wed Jan 16, 2008 9:48 am

Yeah, those who want to weave through traffic would be smart to have a decent grasp of what that traffic might do! I do go up the inside, but only when traffic is stationary or very close to it, and I can be sure it's not about to turn right. Therefore never buses that are about to turn right.....docchevron1472 wrote:I have no problem at all about being overtaken by anything, it's when they undertake I get narked.SamWise wrote: The only thing I do that can piss some people off is that I'll overtake slow moving traffic. Some drivers hate that, but tough luck, I do it safely, and that's what a bike is for!

Especially whe I'm turning left, in a 40foot motor, and some arsehole on a bike (and it's been motorbikes aswell) some steaming up the inside.

I really would kill all of them.

1966 Triumph Herald convertible with big valve twin carb Spitfire head

1973 Bedford Panorama Elite II Bus

1994 2.1TD Citroen XM

1992 Citroen AX Echo 1.4D

1973 Bedford Panorama Elite II Bus

1994 2.1TD Citroen XM

1992 Citroen AX Echo 1.4D

-

docchevron

- The Immoderate half of the admin team

- Posts: 7524

- Joined: Sun Jun 04, 2006 7:03 pm

- Location: A Bucket of Fish

- x 7

Blimey, this is out of date!

Work was slow to non existent on the bus over the winter, partly due to the cold weather, and partly due to being endlessly ill.

Things got further interupted when the local druggie scumbags of Stockwood vandalised K's car.

I got my mate to recover it to the farm, at 3 in the morning, which, even at mates rates, wasn't too cheap.

Oddly, the drop glass was more expensive than the windscreen, no idea why.

Needless to say the channel was rotten too, so I got a shiny new ally one for £14! which was nice.

Fitting the screen was a faff, handily my mate G was on hand to keep the screen in place whilst I pulled the string.

I fitted an alarm, with some help from dad since wires and me just dont get on!

The car now lives at the farm until K finds a suitable place to move to. Stockwood can be left to the ferrile little bastards.

I started getting slightly back into "bus mode" then got diverted again by this:

The replacement tow truck for the very old and tired Leyland Buffalo.

this fella's a Leyland Roadtrain, of 1986 vintage, with spec lift.

It's rather sexy! 14litre NH290 Cummins engine, 8 speed box with a splitter, and sleeper cab. Noice!

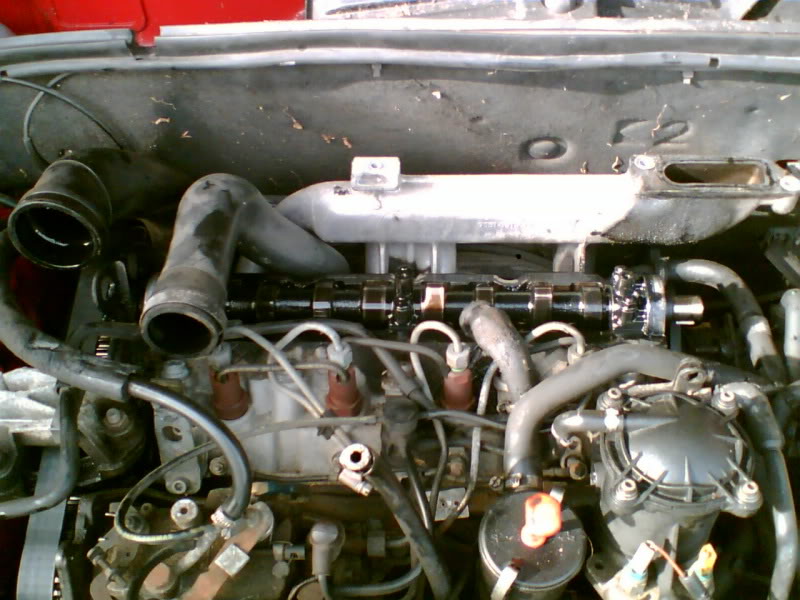

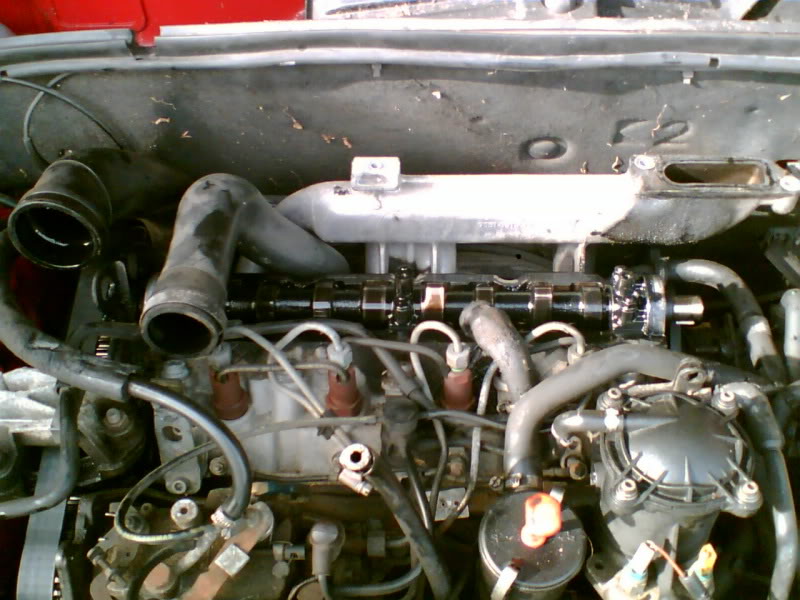

My week off got taken up with this:

That required, er, quite alot, including calipers, discs, pads, octopus, handbrake cables, front hubs, spheres, every bloody oil seal in the engine, cam belt kit etc etc etc, the list went on, but it will become possibly the first ever fully P2'd break.

Whilst I had the engine in bits I thought it would be inpolite not to wham an NA can in it, so I did.

Still, finally I got just about enough health together at the same time to have a pop at the bus.

And thus it goes a bit like this:

Lots of welding, followed by more beating with hammers, followed by some red oxide primer.

What I thought was a fucked shocker bush turned out to be the pivot bolt, the bush was new, so I guess our engineers in work thought the bush was fucked aswell!

The bolt aint available anymore, but I may have a supply sorted

Next came making up new shocker and bump stop mounts:

The little things that have to be right:

The cheap shit aftermarket air guage replaced by a proper OEM Dennis guage.

Next up I replaced the floor bearers and risers on the O/S chassis rail:

Then we collected the spare engine, which I didn't actually need, but the plan is to rebuild the head on that engine, then slap it straight on the lump in 132, along with a new timing case, mains and big ends, oil pump, injectors etc..

Here's the remains of the O/S step riser:

Given it's rotten state I made a new one by hand.

I intended to get some fabricated, but I couldn't work out how the hell I'd collect them since they wont fit in the car!

So I made a new one in two halves:

and welded it all together.

It required a bit of a chop about at the arse end to make it fit on the rear riser perfectley, but it aint bad.

Then I made up the front riser and welded that in, after myself, dad, and Matthew spent about 300 years belting crap out of the old rotten one to get the bugger out:

With that done, the fibreglass wheelarch could go back in.

Which also required all three of us to haul into place:

That leaves this rather large gap:

I always felt it was a pisspoor effort on Plaxtons part not to make proper full arch sections, since all the shite off the wheels is free to land on the chassis crossmember, the step riser and floor bearers.

So, I made this:

Made from a Bristol VR side panel!

I'll do the same for the other side when I get to it.

It's not yet fitted in, as I still have to make some mounting brackets up, which I'll get on to tomorrow.

But it looks a bit like this in the hole:

Which should keep the chassis in good nick for, er, a very long time I hope!

Work was slow to non existent on the bus over the winter, partly due to the cold weather, and partly due to being endlessly ill.

Things got further interupted when the local druggie scumbags of Stockwood vandalised K's car.

I got my mate to recover it to the farm, at 3 in the morning, which, even at mates rates, wasn't too cheap.

Oddly, the drop glass was more expensive than the windscreen, no idea why.

Needless to say the channel was rotten too, so I got a shiny new ally one for £14! which was nice.

Fitting the screen was a faff, handily my mate G was on hand to keep the screen in place whilst I pulled the string.

I fitted an alarm, with some help from dad since wires and me just dont get on!

The car now lives at the farm until K finds a suitable place to move to. Stockwood can be left to the ferrile little bastards.

I started getting slightly back into "bus mode" then got diverted again by this:

The replacement tow truck for the very old and tired Leyland Buffalo.

this fella's a Leyland Roadtrain, of 1986 vintage, with spec lift.

It's rather sexy! 14litre NH290 Cummins engine, 8 speed box with a splitter, and sleeper cab. Noice!

My week off got taken up with this:

That required, er, quite alot, including calipers, discs, pads, octopus, handbrake cables, front hubs, spheres, every bloody oil seal in the engine, cam belt kit etc etc etc, the list went on, but it will become possibly the first ever fully P2'd break.

Whilst I had the engine in bits I thought it would be inpolite not to wham an NA can in it, so I did.

Still, finally I got just about enough health together at the same time to have a pop at the bus.

And thus it goes a bit like this:

Lots of welding, followed by more beating with hammers, followed by some red oxide primer.

What I thought was a fucked shocker bush turned out to be the pivot bolt, the bush was new, so I guess our engineers in work thought the bush was fucked aswell!

The bolt aint available anymore, but I may have a supply sorted

Next came making up new shocker and bump stop mounts:

The little things that have to be right:

The cheap shit aftermarket air guage replaced by a proper OEM Dennis guage.

Next up I replaced the floor bearers and risers on the O/S chassis rail:

Then we collected the spare engine, which I didn't actually need, but the plan is to rebuild the head on that engine, then slap it straight on the lump in 132, along with a new timing case, mains and big ends, oil pump, injectors etc..

Here's the remains of the O/S step riser:

Given it's rotten state I made a new one by hand.

I intended to get some fabricated, but I couldn't work out how the hell I'd collect them since they wont fit in the car!

So I made a new one in two halves:

and welded it all together.

It required a bit of a chop about at the arse end to make it fit on the rear riser perfectley, but it aint bad.

Then I made up the front riser and welded that in, after myself, dad, and Matthew spent about 300 years belting crap out of the old rotten one to get the bugger out:

With that done, the fibreglass wheelarch could go back in.

Which also required all three of us to haul into place:

That leaves this rather large gap:

I always felt it was a pisspoor effort on Plaxtons part not to make proper full arch sections, since all the shite off the wheels is free to land on the chassis crossmember, the step riser and floor bearers.

So, I made this:

Made from a Bristol VR side panel!

I'll do the same for the other side when I get to it.

It's not yet fitted in, as I still have to make some mounting brackets up, which I'll get on to tomorrow.

But it looks a bit like this in the hole:

Which should keep the chassis in good nick for, er, a very long time I hope!

Smokes lots, because enough's enough already!

Far too many BX's, a bus, an ambulance a few trucks, not enough time and never enough cash...

Far too many BX's, a bus, an ambulance a few trucks, not enough time and never enough cash...

-

Philip Chidlow

- Over 2k

- Posts: 11594

- Joined: Fri Oct 07, 2005 1:08 pm

- Location: Chelmsford, Essex

- x 25

-

MULLEY

- Over 2k

- Posts: 8406

- Joined: Thu Jun 22, 2006 11:10 pm

- Location: Derbyshire

- My Cars: 1999 Xsara LX 2.0HDI (90) Hatch - Fern

2002 C5 2.0 HDI (110) Estate - Jasmine - SORN

2011 Mini Cooper D Clubman - SOLD

2016 Mercedes A180D Sport - Auto refinement

1992 TZD Turbo - Bluebell - SORN

1992 TZD Turbo Estate - SORN

1991 Gti 16V - Blaze - crash damaged, will get repaired - SORN

1990 Gti 8Valve SOLD - looks like it's been scrapped

2002 Mini Cooper S - SOLD - i miss this car

1992 TXD - Scrapped in March 2014

1988 CX 25 GTI Turbo2 - SORN

1996 - AX Memphis 1.5D - Dream - SORN - x 8

Shit, all of that done in a day

2002 C5 2.0 HDI Estate - Jasmine - Now SORN

2011 Mini Cooper D Clubman - SOLD

2016 Mercedes A180D Sport - Auto refinement

1992 TZD Turbo - Bluebell - My daily

1991 Gti 16V - Blaze - crash damaged, will get repaired.

1990 Gti 8Valve SOLD - looks like it's been scrapped

2002 Mini Cooper S - SOLD - i miss this car

1992 TXD - Scrapped in March 2014

1988 CX 25 GTI Turbo2 - SORN

1996 - AX Memphis 1.5D - Dream - SORN

I'm not just a username, i'm also called Matthew.

2011 Mini Cooper D Clubman - SOLD

2016 Mercedes A180D Sport - Auto refinement

1992 TZD Turbo - Bluebell - My daily

1991 Gti 16V - Blaze - crash damaged, will get repaired.

1990 Gti 8Valve SOLD - looks like it's been scrapped

2002 Mini Cooper S - SOLD - i miss this car

1992 TXD - Scrapped in March 2014

1988 CX 25 GTI Turbo2 - SORN

1996 - AX Memphis 1.5D - Dream - SORN

I'm not just a username, i'm also called Matthew.

-

Tim Leech

- Over 2k

- Posts: 15618

- Joined: Tue Apr 15, 2008 11:12 am

- Location: Derbyshire

- My Cars: Various

- x 160

-

docchevron

- The Immoderate half of the admin team

- Posts: 7524

- Joined: Sun Jun 04, 2006 7:03 pm

- Location: A Bucket of Fish

- x 7

The truck is just awesome Dave.

14 litres of Cummins dieselly greatness, and the biggest turbo I have EVER seen!

But meh, thats what friends are right?

Ya know, a friend in need is a bloody PITA and all that.

Wouldn't be without her though.

Love the piccy Marty!

I might have to print that and stick one on the door!

14 litres of Cummins dieselly greatness, and the biggest turbo I have EVER seen!

Ah, K, er, well, K is my best mate, longtime soulmate kinda person, at one point for a while Mrs. Doc, although that was many many years ago now, she's also a massive pain in the arse and infuriating.Tim wrote:Am I being thick but who is "K"?

But meh, thats what friends are right?

Ya know, a friend in need is a bloody PITA and all that.

Wouldn't be without her though.

Love the piccy Marty!

I might have to print that and stick one on the door!

Smokes lots, because enough's enough already!

Far too many BX's, a bus, an ambulance a few trucks, not enough time and never enough cash...

Far too many BX's, a bus, an ambulance a few trucks, not enough time and never enough cash...

-

docchevron

- The Immoderate half of the admin team

- Posts: 7524

- Joined: Sun Jun 04, 2006 7:03 pm

- Location: A Bucket of Fish

- x 7

Today....I took the wheelarch skirt panel off to make it easier to get the new arch panel in, and discovered yet more rot!

Ok, you cant really see it in the picture, but there's a pair of body pillars (ally) hidden in the picture by the strips of neoprene.

These are attached to the body bearer panels by bits of angle iron, drilled and cross bolted through the uprights.

Only they aint anymore! The angle has rotted away completely and the rear most pillar is pretty much free floating!

The mass of corrosion here is due to the heater pipe on the other side of the stress panel thats been leaking for years.

Said leak had rotted the floor out already, but I hadn't realised until today it had migrated through the gap between the floor and stress panel and had been eating away at the structure.

Initially I thought "sod it, red oxide, chassis black, fit new skirt panel, forget", but, well, thats not right so the pillar will need supporting whilst some new bits of angle are welded to the bearer.

It's no wonder these things rattle so much, I'm guessing most of the fleet now have free floating bodywork to go with the non existent chassis.

Still, the arch panel is now suitably attached to the bus, held along it's lower edge by another new piece of 50x50 6mm angle iron welded to the chassis riser at the inner edge, and the body bearer on the outer edge, so it wont fall off anytime soon!

Here's the front O/S step riser:

Despite being super careful measuring it all up when I made them, I couldn't work out why there was a 1/2" gap between the top of the riser and the side moulding on the inner stress panel that the floor sits on.

So I measured it against the N/S stress panel and discovered that there's a 1/2" difference across the bus.

Coach built stuff huh!

Turns out that most were all the same, or worse, so I'm told..

The bodies were built by hand by teams of two people. It seems they never bothered to actually measure one side against the other and worked entirely independently of eachother, hence some wildly differing panel gaps etc.

I could drill all the hook bolts out and lower the O/S stress panel, but I'm not sure I want to remove such a large and well strung panel for the sake of 1/2" I can hide under the wood by cutting some extra out with the router.

I get the impression the panel will go PING if I drill it off, the body could shift and then it'll be a right pig to get it back into shape.

Old floor gets temporarily laid down so I know where to drill through the riser and bearers to cut some threads for the seat bolts.

So, it's getting to look a bit more complete now.

Might have some tyres sorted, there will be some wood arriving with a pair of batteries in the next couple of weeks, so I'm itching to get the contact adhesive out and slap some diptac flooring back down![/quote]

Ok, you cant really see it in the picture, but there's a pair of body pillars (ally) hidden in the picture by the strips of neoprene.

These are attached to the body bearer panels by bits of angle iron, drilled and cross bolted through the uprights.

Only they aint anymore! The angle has rotted away completely and the rear most pillar is pretty much free floating!

The mass of corrosion here is due to the heater pipe on the other side of the stress panel thats been leaking for years.

Said leak had rotted the floor out already, but I hadn't realised until today it had migrated through the gap between the floor and stress panel and had been eating away at the structure.

Initially I thought "sod it, red oxide, chassis black, fit new skirt panel, forget", but, well, thats not right so the pillar will need supporting whilst some new bits of angle are welded to the bearer.

It's no wonder these things rattle so much, I'm guessing most of the fleet now have free floating bodywork to go with the non existent chassis.

Still, the arch panel is now suitably attached to the bus, held along it's lower edge by another new piece of 50x50 6mm angle iron welded to the chassis riser at the inner edge, and the body bearer on the outer edge, so it wont fall off anytime soon!

Here's the front O/S step riser:

Despite being super careful measuring it all up when I made them, I couldn't work out why there was a 1/2" gap between the top of the riser and the side moulding on the inner stress panel that the floor sits on.

So I measured it against the N/S stress panel and discovered that there's a 1/2" difference across the bus.

Coach built stuff huh!

Turns out that most were all the same, or worse, so I'm told..

The bodies were built by hand by teams of two people. It seems they never bothered to actually measure one side against the other and worked entirely independently of eachother, hence some wildly differing panel gaps etc.

I could drill all the hook bolts out and lower the O/S stress panel, but I'm not sure I want to remove such a large and well strung panel for the sake of 1/2" I can hide under the wood by cutting some extra out with the router.

I get the impression the panel will go PING if I drill it off, the body could shift and then it'll be a right pig to get it back into shape.

Old floor gets temporarily laid down so I know where to drill through the riser and bearers to cut some threads for the seat bolts.

So, it's getting to look a bit more complete now.

Might have some tyres sorted, there will be some wood arriving with a pair of batteries in the next couple of weeks, so I'm itching to get the contact adhesive out and slap some diptac flooring back down![/quote]

Smokes lots, because enough's enough already!

Far too many BX's, a bus, an ambulance a few trucks, not enough time and never enough cash...

Far too many BX's, a bus, an ambulance a few trucks, not enough time and never enough cash...

-

CitroXim

- Sir Jim of the Databases

- Posts: 788

- Joined: Wed Oct 31, 2007 9:08 pm

- Location: Newport Pagnell

- x 2

Looking good Doc  Even more of a Herculean task than it first appeared by the looks of it

Even more of a Herculean task than it first appeared by the looks of it  but with every bit of grot gone means there's just that bit less to do..

but with every bit of grot gone means there's just that bit less to do..

Speaking of "K" it sounds very much like the relationship I enjoy with the ex Mrs. CitroXim They can be good and like "K" she is a pain in the arse often. But hey, that's life..

They can be good and like "K" she is a pain in the arse often. But hey, that's life..

Yesterday was typical. "Can you come with me to IKEA Jim? I need you and your estate. I can't lift the box and it won't go in the back of my car.."

She's still a very good mate though and knows me better than anyone.

Got a rude awakening this morning. Thought, for once, I'd lay in and not get up too early, it being Easter Sunday and all that. Phone rang at 06:30. It was Siany, "Dad my bikes' broken. Can you come and help me with my paper round please <sob>?"

So much for a lie in Kids, you'll do anything for - just like you will for "K" Doc...

Kids, you'll do anything for - just like you will for "K" Doc...

Speaking of "K" it sounds very much like the relationship I enjoy with the ex Mrs. CitroXim

Yesterday was typical. "Can you come with me to IKEA Jim? I need you and your estate. I can't lift the box and it won't go in the back of my car.."

She's still a very good mate though and knows me better than anyone.

Got a rude awakening this morning. Thought, for once, I'd lay in and not get up too early, it being Easter Sunday and all that. Phone rang at 06:30. It was Siany, "Dad my bikes' broken. Can you come and help me with my paper round please <sob>?"

So much for a lie in

Jim

'98 Xantia 1.9TD in Red - Gabriel the Bus...

'96 Xantia Activa in Red - My favourite toy...

'07 Pug 207 in Blue - The Deathtrap...

'15 Giant Defy Bike in Blue - Daily rider...

'16 Giant TCR Bike in Black/Lime Green - Fine weather only...

'98 Xantia 1.9TD in Red - Gabriel the Bus...

'96 Xantia Activa in Red - My favourite toy...

'07 Pug 207 in Blue - The Deathtrap...

'15 Giant Defy Bike in Blue - Daily rider...

'16 Giant TCR Bike in Black/Lime Green - Fine weather only...

-

docchevron

- The Immoderate half of the admin team

- Posts: 7524

- Joined: Sun Jun 04, 2006 7:03 pm

- Location: A Bucket of Fish

- x 7

Ditto and spot on!CitroXim wrote: She's still a very good mate though and knows me better than anyone.

Took her and the puppies to Brean today, for a run on the beach.

I'm bloody knackered now!

However tired those doggies get, they'll still go all day and night chasing sticks!

Happily I dont have kids, the two puppies are plenty!

The bus is behind schedule, I had wanted to have the back finished by now, inside and out.

But given the lack of progress over winter, and that I hadn't expected the over axle chassis rails to be non existent, in terms of man hours I'm probably a bit ahead of the original schedule as planned, given the amount of extra work I hadn't anticipated.

It still amazes me that the old Bristol I had was in infinitley better condition bodily and structurally, and that is now 40 years old!

I still believe that once the back end is finished I should rip through the rest pretty quickly.

Until I get to the front arches, everything has to come off and be made from scratch at the front end, since it's all bodged to hell, and nothing fits.

Smokes lots, because enough's enough already!

Far too many BX's, a bus, an ambulance a few trucks, not enough time and never enough cash...

Far too many BX's, a bus, an ambulance a few trucks, not enough time and never enough cash...

-

docchevron

- The Immoderate half of the admin team

- Posts: 7524

- Joined: Sun Jun 04, 2006 7:03 pm

- Location: A Bucket of Fish

- x 7

Turning to the N/S...

Method as per O/S, but a bit quicker due to better weather, and having a better idea of what I'm doing now:

The actual chassis rail on the N/S is in better shape than the O/S rail was, only requiring a bit of plating around the cross member welds, and at the very front where it has disintegrated.

The KwaLitY floor riser... That'll take a 16stone bloke standing on it huh?!

Well, no, since it was not actually attached anymore, meaning that 9' of the floor bearer was being supported entirely by the front N/S step riser, which, in itself has disintegrated.

So, exactley as the other side, a new piece of floor bearer gets welded in.

The original stuff was 50x50 3mm angle, the new stuff is all 50x50 6mm. So it should last a bit longer!

The angle atop the chassis rail was also added to the O/S, and does two things.

It adds some strength to the bump stop and shocker mounts, and fills the gap between the bearer and chassis (after a small filler strip is welded in) which keeps all the shit off the road wheels away from the step riser and inner side of the chassis.

Why Plaxtons didn't do something similar I do not know..

I love red oxide!

After the remains of all the P clips were removed along with the two wiring looms and heater pipe, it all gets beaten with hammer, rodded and painted.

Again like the other side the inner section of the chassis rail is filled with waxoyl.

Needless to say the bolts that secured the axle levelling valve to the rail were rotted away to sod all. It was only the fact that the valve had rusted to the chassis that stopped it falling off.

It's currentley loitering on the side of the diff housing, awaiting some shiny new bolts.

Again, like the O/S, the N/S step riser is made in two halves, folded in work, then welded together before getting the red oxide treatment.

Sexy? Well, it's heavy!

Not yet welded in to the bus, but placed where it needs to be to make any fine adjustments to the metal work around it, and ensure it actually fits.

It does.

Old floor gets temporarily laid down, again to check both sides are even, and to ensure it's all square.

It is.

So, not as much as I hoped to do this week. But I am quite happy with progress now.

A couple of weekends more weldage, and I can cut some new wood, fit it all up and get the seats back in!

Then we move on to the ladder chassis....

Method as per O/S, but a bit quicker due to better weather, and having a better idea of what I'm doing now:

The actual chassis rail on the N/S is in better shape than the O/S rail was, only requiring a bit of plating around the cross member welds, and at the very front where it has disintegrated.

The KwaLitY floor riser... That'll take a 16stone bloke standing on it huh?!

Well, no, since it was not actually attached anymore, meaning that 9' of the floor bearer was being supported entirely by the front N/S step riser, which, in itself has disintegrated.

So, exactley as the other side, a new piece of floor bearer gets welded in.

The original stuff was 50x50 3mm angle, the new stuff is all 50x50 6mm. So it should last a bit longer!

The angle atop the chassis rail was also added to the O/S, and does two things.

It adds some strength to the bump stop and shocker mounts, and fills the gap between the bearer and chassis (after a small filler strip is welded in) which keeps all the shit off the road wheels away from the step riser and inner side of the chassis.

Why Plaxtons didn't do something similar I do not know..

I love red oxide!

After the remains of all the P clips were removed along with the two wiring looms and heater pipe, it all gets beaten with hammer, rodded and painted.

Again like the other side the inner section of the chassis rail is filled with waxoyl.

Needless to say the bolts that secured the axle levelling valve to the rail were rotted away to sod all. It was only the fact that the valve had rusted to the chassis that stopped it falling off.

It's currentley loitering on the side of the diff housing, awaiting some shiny new bolts.

Again, like the O/S, the N/S step riser is made in two halves, folded in work, then welded together before getting the red oxide treatment.

Sexy? Well, it's heavy!

Not yet welded in to the bus, but placed where it needs to be to make any fine adjustments to the metal work around it, and ensure it actually fits.

It does.

Old floor gets temporarily laid down, again to check both sides are even, and to ensure it's all square.

It is.

So, not as much as I hoped to do this week. But I am quite happy with progress now.

A couple of weekends more weldage, and I can cut some new wood, fit it all up and get the seats back in!

Then we move on to the ladder chassis....

Smokes lots, because enough's enough already!

Far too many BX's, a bus, an ambulance a few trucks, not enough time and never enough cash...

Far too many BX's, a bus, an ambulance a few trucks, not enough time and never enough cash...

-

Philip Chidlow

- Over 2k

- Posts: 11594

- Joined: Fri Oct 07, 2005 1:08 pm

- Location: Chelmsford, Essex

- x 25