The End of Everything

-

stuart_hedges

- 1K Away

- Posts: 1679

- Joined: Mon Oct 03, 2005 10:35 am

- Location: Surrey

I remember Badgerline with great fondness, they used to run the route out to my Grandma's house! It wouldn't have been 132 as they used minibuses on that route, but out of all the companies that have serviced it (Bristol's bus service is a total mess) Badger is one that sticks out in my memory.

Doc, you'll have no shortage of unskilled labour from me while I'm in Bristol through September, so get thinking about easy, non-technical jobs I can be getting on with!

Doc, you'll have no shortage of unskilled labour from me while I'm in Bristol through September, so get thinking about easy, non-technical jobs I can be getting on with!

-

docchevron

- The Immoderate half of the admin team

- Posts: 7524

- Joined: Sun Jun 04, 2006 7:03 pm

- Location: A Bucket of Fish

- x 7

Erm, hard to say for certain mate. It's on it's third speedo head!MULLEY wrote:Just out of interest, how many miles are on your Bus?

It's lower milage than any other P1 Lance since it had two MAJOR front end smashes and spent just over two years off the road because of them.

I'd guess that it's somewhere between 3 and 3.5 million miles, not bad since it's still on it's original engine and gearbox, although it's had 4 differentials!

The highest milage Lance was 133, that accrued 4.3 million miles in 15 years!

Hhmm! Shame you've only got a month really mate, I could keep you busy for years!Disco Stu wrote:Doc, you'll have no shortage of unskilled labour from me while I'm in Bristol through September, so get thinking about easy, non-technical jobs I can be getting on with!

Any good with woodwork and drilling rivits?!

Smokes lots, because enough's enough already!

Far too many BX's, a bus, an ambulance a few trucks, not enough time and never enough cash...

Far too many BX's, a bus, an ambulance a few trucks, not enough time and never enough cash...

-

Philip Chidlow

- Over 2k

- Posts: 11594

- Joined: Fri Oct 07, 2005 1:08 pm

- Location: Chelmsford, Essex

- x 25

Probably of no interest, but there's a place near me that sells off MOD vehicles plus coaches and other stuff.

Like this:

http://www.witham-sv.com/infopage.php?ID=44&Overide=0

Like this:

http://www.witham-sv.com/infopage.php?ID=44&Overide=0

• 1992 Citroen BX TZD Turbo Hurricane

• 2006 Xsara Picasso 1.6 16v

• 2006 Xsara Picasso 1.6 16v

-

MULLEY

- Over 2k

- Posts: 8406

- Joined: Thu Jun 22, 2006 11:10 pm

- Location: Derbyshire

- My Cars: 1999 Xsara LX 2.0HDI (90) Hatch - Fern

2002 C5 2.0 HDI (110) Estate - Jasmine - SORN

2011 Mini Cooper D Clubman - SOLD

2016 Mercedes A180D Sport - Auto refinement

1992 TZD Turbo - Bluebell - SORN

1992 TZD Turbo Estate - SORN

1991 Gti 16V - Blaze - crash damaged, will get repaired - SORN

1990 Gti 8Valve SOLD - looks like it's been scrapped

2002 Mini Cooper S - SOLD - i miss this car

1992 TXD - Scrapped in March 2014

1988 CX 25 GTI Turbo2 - SORN

1996 - AX Memphis 1.5D - Dream - SORN - x 8

Cheers for the info, i had no idea they would do that kind of mileage. I guess when you take that into account, they are very well made. Can't think of too many cars that could do that mileage & carry loads of psgr's at the same time, amazing when you think about it.

2002 C5 2.0 HDI Estate - Jasmine - Now SORN

2011 Mini Cooper D Clubman - SOLD

2016 Mercedes A180D Sport - Auto refinement

1992 TZD Turbo - Bluebell - My daily

1991 Gti 16V - Blaze - crash damaged, will get repaired.

1990 Gti 8Valve SOLD - looks like it's been scrapped

2002 Mini Cooper S - SOLD - i miss this car

1992 TXD - Scrapped in March 2014

1988 CX 25 GTI Turbo2 - SORN

1996 - AX Memphis 1.5D - Dream - SORN

I'm not just a username, i'm also called Matthew.

2011 Mini Cooper D Clubman - SOLD

2016 Mercedes A180D Sport - Auto refinement

1992 TZD Turbo - Bluebell - My daily

1991 Gti 16V - Blaze - crash damaged, will get repaired.

1990 Gti 8Valve SOLD - looks like it's been scrapped

2002 Mini Cooper S - SOLD - i miss this car

1992 TXD - Scrapped in March 2014

1988 CX 25 GTI Turbo2 - SORN

1996 - AX Memphis 1.5D - Dream - SORN

I'm not just a username, i'm also called Matthew.

-

docchevron

- The Immoderate half of the admin team

- Posts: 7524

- Joined: Sun Jun 04, 2006 7:03 pm

- Location: A Bucket of Fish

- x 7

Buses are odd like that Mulley, they aint really designed with a mileage in mind, they are designed to last a set number years and thats it.

On the whole double deck design life is 20 years, coaches 18 years and single decks 15 years.

Nearly all make that target, but by then they are totally buggered. 132 is no exception!

Pilsy and Vanny are down visiting at the mo, so they turned up with Smiffy, Vanny donned his overalls and commenced ripping the floor up!

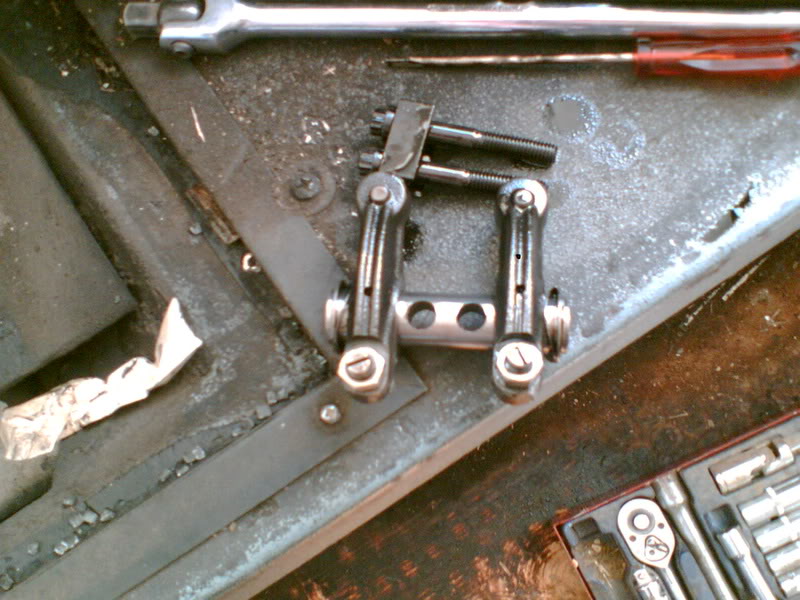

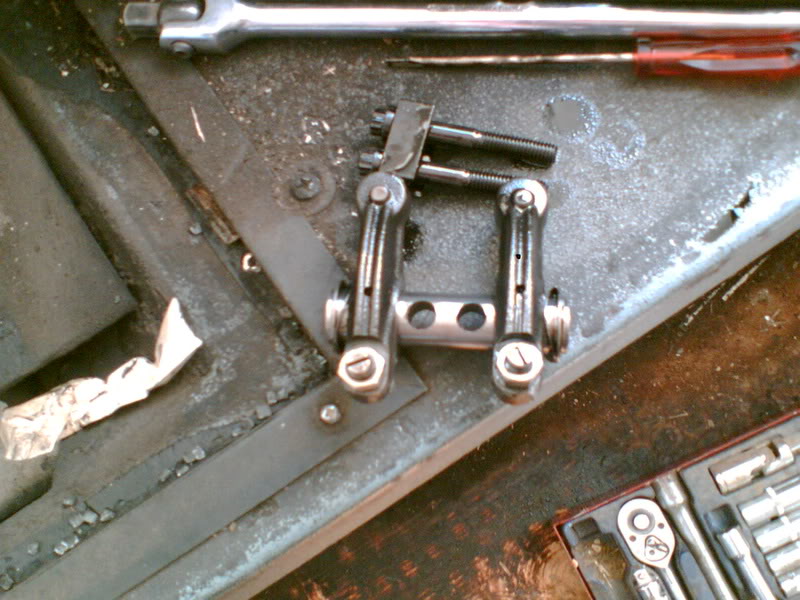

Before the masses of dad, Vanny, Pilsy, Smiffy and Matthew Parker arrived I commenced building the engine back up after collecting a shiny new rocker shaft:

Then I set the tappets up on all the cylinders.

Some of the gaps were so wide you could literally have driven a bloody bus through them.

Some were so bad you could actually lift the pushrods out of the engine!

The head will have to come off since some of the valve stem heads are so badly mullered the rockers are acting on the valve spring caps...

But for now it sounds better than it has for, er, a bloody long time.

It's soooo smooooooooooth

Ok, it sounds shit on the vid, but only because the little mic on the phone just cannot cope with the decibel output of 8.3 litres of Cummins diesly greatness, but really, it sounds bloody lovely.

Alas the same cannot be said of the rest of it!

Theres rot EVERYWHERE.

I'm not worried about the stress panels and floor bearers since it's all nice and simple to hack out and replace, but the cross member on the chassis that supports the rear air spring pedestals is badly rotten. So much so that the O/S spring pedestal has collapsed the cross member, and it's a seriousley substantial piece of metal, so replacing that will be fun...

A view with the floor out showing the top of the rear axle and along the floor bearer stress panels, all of which will be replaced with galvanised steel and smothered in paint!

In for a penny...

The invoice arrived for it this morning, so at least I can now actually pay for it and forget about the money aspect of it for a while...

On the whole double deck design life is 20 years, coaches 18 years and single decks 15 years.

Nearly all make that target, but by then they are totally buggered. 132 is no exception!

Pilsy and Vanny are down visiting at the mo, so they turned up with Smiffy, Vanny donned his overalls and commenced ripping the floor up!

Before the masses of dad, Vanny, Pilsy, Smiffy and Matthew Parker arrived I commenced building the engine back up after collecting a shiny new rocker shaft:

Then I set the tappets up on all the cylinders.

Some of the gaps were so wide you could literally have driven a bloody bus through them.

Some were so bad you could actually lift the pushrods out of the engine!

The head will have to come off since some of the valve stem heads are so badly mullered the rockers are acting on the valve spring caps...

But for now it sounds better than it has for, er, a bloody long time.

It's soooo smooooooooooth

Ok, it sounds shit on the vid, but only because the little mic on the phone just cannot cope with the decibel output of 8.3 litres of Cummins diesly greatness, but really, it sounds bloody lovely.

Alas the same cannot be said of the rest of it!

Theres rot EVERYWHERE.

I'm not worried about the stress panels and floor bearers since it's all nice and simple to hack out and replace, but the cross member on the chassis that supports the rear air spring pedestals is badly rotten. So much so that the O/S spring pedestal has collapsed the cross member, and it's a seriousley substantial piece of metal, so replacing that will be fun...

A view with the floor out showing the top of the rear axle and along the floor bearer stress panels, all of which will be replaced with galvanised steel and smothered in paint!

In for a penny...

The invoice arrived for it this morning, so at least I can now actually pay for it and forget about the money aspect of it for a while...

Smokes lots, because enough's enough already!

Far too many BX's, a bus, an ambulance a few trucks, not enough time and never enough cash...

Far too many BX's, a bus, an ambulance a few trucks, not enough time and never enough cash...

-

docchevron

- The Immoderate half of the admin team

- Posts: 7524

- Joined: Sun Jun 04, 2006 7:03 pm

- Location: A Bucket of Fish

- x 7

I'm rather happy, myself an Matthew spent several hours attacking the chassis, and we finally found some actual proper metal!

Ok, it's only about 3" by 1", but it's the first we've xome across that hasn't been rotten, so things are looking up!

Got the rest of the floor out of the back too:

The O/S floor bearers and stress panels aren't quite as bad as the N/S, but they are still fairly unpleasant.

All will be hacked out and replaced.

I'm going to try and talk the local industrial ducting fabricators into making up new stress panels from 16 guage galvanised steel, the rest I'll make from hefty angle iron.

This is the really bad outrigger where the air spring pedestal is slowley sinking through it:

Having cleaned all the rotten shite off it, it's actually not as bad as it looked, but will require some serious fabrication and welding with 3/16 and 1/4 " plate.

After years of having painfully harsh suspension I lowered the rear ride height today, so it should actually have suspension at the back end again, there's only one height controller for the rear axle, and having the floor out makes it a good deal easier to get at.

The control rod and rubber ends have been replaced recentley, so quite why the engineers couldn't be arsed to actually set the pressures properly at the same time I have no idea..

Alas the front has a height controller either side, and both control rods are rotten and seized, so I couldn't adjust them, at the moment the bus is on the piss to the O/S, but I'll get some new rods and rubber ends in the week so next weekend I can get the front about right and see how the suspension feels.

Fun and games.

Ok, it's only about 3" by 1", but it's the first we've xome across that hasn't been rotten, so things are looking up!

Got the rest of the floor out of the back too:

The O/S floor bearers and stress panels aren't quite as bad as the N/S, but they are still fairly unpleasant.

All will be hacked out and replaced.

I'm going to try and talk the local industrial ducting fabricators into making up new stress panels from 16 guage galvanised steel, the rest I'll make from hefty angle iron.

This is the really bad outrigger where the air spring pedestal is slowley sinking through it:

Having cleaned all the rotten shite off it, it's actually not as bad as it looked, but will require some serious fabrication and welding with 3/16 and 1/4 " plate.

After years of having painfully harsh suspension I lowered the rear ride height today, so it should actually have suspension at the back end again, there's only one height controller for the rear axle, and having the floor out makes it a good deal easier to get at.

The control rod and rubber ends have been replaced recentley, so quite why the engineers couldn't be arsed to actually set the pressures properly at the same time I have no idea..

Alas the front has a height controller either side, and both control rods are rotten and seized, so I couldn't adjust them, at the moment the bus is on the piss to the O/S, but I'll get some new rods and rubber ends in the week so next weekend I can get the front about right and see how the suspension feels.

Fun and games.

Smokes lots, because enough's enough already!

Far too many BX's, a bus, an ambulance a few trucks, not enough time and never enough cash...

Far too many BX's, a bus, an ambulance a few trucks, not enough time and never enough cash...

-

Philip Chidlow

- Over 2k

- Posts: 11594

- Joined: Fri Oct 07, 2005 1:08 pm

- Location: Chelmsford, Essex

- x 25

-

mat_fenwick

- Moderator

- Posts: 7328

- Joined: Tue Sep 20, 2005 4:08 pm

- Location: North Wales

- x 20

Good work Chris, you probably already know this but if you are welding galvanised apparently it gives off some nasty fumes. Mind you having a fag in your mouth may well filter some of them out...

Oh, and you'd better have a look at this thread, Todd has made you an offer you won't be able to refuse!

Oh, and you'd better have a look at this thread, Todd has made you an offer you won't be able to refuse!

-

docchevron

- The Immoderate half of the admin team

- Posts: 7524

- Joined: Sun Jun 04, 2006 7:03 pm

- Location: A Bucket of Fish

- x 7

So, it's been a while!

Not that I've been that idle..

Work continues on the bus, although calling it a bus is pushing it a bit I fear, describing it as 8965KGs of rust would be more accurate..

Finally got the floor risers out after 3 days of hacking, hitting and grinding:

The O/S riser comes out complete with the drop gangway floor bearers, which are actually in pretty good nick.

I've still to remove the riser across the front of the step, so that'll be next weekends job.

Rather alarmingly after removing the risers the extent of the chassis corrosion becomes painfully apparent....

This was the N/S chassis rail running over the rear axle, there's fuck all left of it.

That would be the front end of the same rail, again, there's nothing left of it. It has all the integrity of dosiers on WMD..

The O/S faired better, although that really isn't saying much TBH..

Here's the front end of the raised rail on the O/S. again, corrosion is horrific, but not quite as bad as t'other side, so almost something to smile about I guess...

This is looking down on the O/S rail, you can see how thick it was once where the rot is still held to the remaining chassis by the air pipe clamp!

Here's the O/S shock absorber mount, also fucked beyond belief, again as with all things DENNIS, it's welded to the chassis, although it's begining to unpeel, and is rather complicated as there are two shockers each side.

The N/S is again much worse and both will have to be hacked off and fabricated from scratch.

The way I see it, I've got two options with the chassis rails.

A: dismantle the body completley rearward from the step, remove engine / gearbox, cut the chassis in half, remove both the rotted rails and have new ones fabricated then weld it all back together, which would be the best approach I guess, but an undescribable amount of work, and cash..

B: grind the rails back until something resembling shiny metal is found, then get some 1/4" plate and construct two new tubes over the existing rails, seam welded all the way along, around the cross members, down the chassis risers and onto the front low height part of the chassis (which is actually a DENNIS Fire engine..)

Right now option B is looking the only realistic way forward unless I just give up, which for a few minutes I did seriousley consider doing.

Moving on from the chassis...

Well, it doesn't get any better really!

The company no longer use the wheel nut tags you see on most commercial vehicles (the little yellow pointer tags on teh nuts like) on the front axle, because The big cheese dude in Aberdeen likes shiny chrome trims, yes, he is a cock.

I think the fitters are now so worried about wheels falling off (it's happened before) that they now REALLY fucking do the front nuts up to way past the 480lb / ft they should be.

In short the studs on both front hubs are fucked.

Replacable, but not cheap...

Also sadly the drums are rotten and quite worn, and they aint that old! It does rather highlight how hard they get driven...it ate a set of tyres in three months and the front drums have been on it for maybe 9 months..

Further bad news came when I removed the N/S skirt panels.

Well there's a surprise! More rot!

The body bearer is rather FUBAR, as is the upright pillar TBH.. Bi metallic corrosion FTL.

And it keeps getting worse!

Obviousley at some stage it's had a major side impact (although I must admit I dont remember such an occurance but the evidence is, well, self evident!) and has been really pitifully repaired by the usual morons that shouldn't really be allowed anywhere near buses..

The rear end of the body bearer has been cut out, and re welded.

I think it's been replaced, and I also suspect that when it was cut out no acroprop was used to support the body pillar allowing it to drop, which explains why the replacement section of body bearer has been welded in on the piss (it drops badly as it approaches the N/S/R wheelarch).

The quality of the weld is shit, and not even finished to the top of the bearer.

Here's the pisspoor repair weld..

and at the rear end, where it should be flush with the stress panel above it, but isn't.

This also explains why the N/S of the body is drooping more than the O/S.

So, that'll have to come out and be welded in properly, whilst the body is jacked and propped.

Maybe my initial estimation of 10years to finish it was actually about right!

Bear in mind, this thing still has a Class 6 MoT until Oct 17, and we still run a fleet of them, and they are all this bad, or worse, and still carrying fare paying punters!

Scary aint it!

Not that I've been that idle..

Work continues on the bus, although calling it a bus is pushing it a bit I fear, describing it as 8965KGs of rust would be more accurate..

Finally got the floor risers out after 3 days of hacking, hitting and grinding:

The O/S riser comes out complete with the drop gangway floor bearers, which are actually in pretty good nick.

I've still to remove the riser across the front of the step, so that'll be next weekends job.

Rather alarmingly after removing the risers the extent of the chassis corrosion becomes painfully apparent....

This was the N/S chassis rail running over the rear axle, there's fuck all left of it.

That would be the front end of the same rail, again, there's nothing left of it. It has all the integrity of dosiers on WMD..

The O/S faired better, although that really isn't saying much TBH..

Here's the front end of the raised rail on the O/S. again, corrosion is horrific, but not quite as bad as t'other side, so almost something to smile about I guess...

This is looking down on the O/S rail, you can see how thick it was once where the rot is still held to the remaining chassis by the air pipe clamp!

Here's the O/S shock absorber mount, also fucked beyond belief, again as with all things DENNIS, it's welded to the chassis, although it's begining to unpeel, and is rather complicated as there are two shockers each side.

The N/S is again much worse and both will have to be hacked off and fabricated from scratch.

The way I see it, I've got two options with the chassis rails.

A: dismantle the body completley rearward from the step, remove engine / gearbox, cut the chassis in half, remove both the rotted rails and have new ones fabricated then weld it all back together, which would be the best approach I guess, but an undescribable amount of work, and cash..

B: grind the rails back until something resembling shiny metal is found, then get some 1/4" plate and construct two new tubes over the existing rails, seam welded all the way along, around the cross members, down the chassis risers and onto the front low height part of the chassis (which is actually a DENNIS Fire engine..)

Right now option B is looking the only realistic way forward unless I just give up, which for a few minutes I did seriousley consider doing.

Moving on from the chassis...

Well, it doesn't get any better really!

The company no longer use the wheel nut tags you see on most commercial vehicles (the little yellow pointer tags on teh nuts like) on the front axle, because The big cheese dude in Aberdeen likes shiny chrome trims, yes, he is a cock.

I think the fitters are now so worried about wheels falling off (it's happened before) that they now REALLY fucking do the front nuts up to way past the 480lb / ft they should be.

In short the studs on both front hubs are fucked.

Replacable, but not cheap...

Also sadly the drums are rotten and quite worn, and they aint that old! It does rather highlight how hard they get driven...it ate a set of tyres in three months and the front drums have been on it for maybe 9 months..

Further bad news came when I removed the N/S skirt panels.

Well there's a surprise! More rot!

The body bearer is rather FUBAR, as is the upright pillar TBH.. Bi metallic corrosion FTL.

And it keeps getting worse!

Obviousley at some stage it's had a major side impact (although I must admit I dont remember such an occurance but the evidence is, well, self evident!) and has been really pitifully repaired by the usual morons that shouldn't really be allowed anywhere near buses..

The rear end of the body bearer has been cut out, and re welded.

I think it's been replaced, and I also suspect that when it was cut out no acroprop was used to support the body pillar allowing it to drop, which explains why the replacement section of body bearer has been welded in on the piss (it drops badly as it approaches the N/S/R wheelarch).

The quality of the weld is shit, and not even finished to the top of the bearer.

Here's the pisspoor repair weld..

and at the rear end, where it should be flush with the stress panel above it, but isn't.

This also explains why the N/S of the body is drooping more than the O/S.

So, that'll have to come out and be welded in properly, whilst the body is jacked and propped.

Maybe my initial estimation of 10years to finish it was actually about right!

Bear in mind, this thing still has a Class 6 MoT until Oct 17, and we still run a fleet of them, and they are all this bad, or worse, and still carrying fare paying punters!

Scary aint it!

Smokes lots, because enough's enough already!

Far too many BX's, a bus, an ambulance a few trucks, not enough time and never enough cash...

Far too many BX's, a bus, an ambulance a few trucks, not enough time and never enough cash...

-

Philip Chidlow

- Over 2k

- Posts: 11594

- Joined: Fri Oct 07, 2005 1:08 pm

- Location: Chelmsford, Essex

- x 25

Makes you wonder how the bus designers, builders and operators get away with it. Appalling.

And it reinforces my belief that salt shouldn't be plastered all over our roads at the first sign of winter. What happens on the continent? Do they use salty grit everywhere?

And it reinforces my belief that salt shouldn't be plastered all over our roads at the first sign of winter. What happens on the continent? Do they use salty grit everywhere?

• 1992 Citroen BX TZD Turbo Hurricane

• 2006 Xsara Picasso 1.6 16v

• 2006 Xsara Picasso 1.6 16v

-

M

In reply to whcih:docchevron1472 wrote: Scary aint it!

M wrote:

Chris, weigh it in and go an but something less rusty instead, say a nice Alfasud that has ived by the coast at Blackpool parked on the sea front all its life and been under water once as well.....

I am, sir, in awe of your gas axe skillorz if you persist with that buz.

-

jonathan_dyane

- BXpert

- Posts: 975

- Joined: Sat Feb 09, 2008 7:15 pm

- Location: Liverpool

-

DavidRutherford

- BX Digit man!

- Posts: 2706

- Joined: Wed May 18, 2005 5:07 pm

- Location: Placing comments on YouTube.

It has to be said though, given the option I'd much rather weld large chunks of bus chassis than weld wafer-thin car bodywork. Anything under about 2mm is rather annoying to weld together.

Having seen this bus in the flesh, it does make me worry about the stuff on the roads at the moment.

Having seen this bus in the flesh, it does make me worry about the stuff on the roads at the moment.

this might be a signature

-

Way2go

- Over 2k

- Posts: 7279

- Joined: Fri Jan 13, 2006 3:15 pm

- Location: RCoBerkshire

- x 2

Can only conclude that the old Routemasters and RT's must have been a better quality build as they over extended their service life by a massive time!DavidRutherford wrote: Having seen this bus in the flesh, it does make me worry about the stuff on the roads at the moment.

Still, I guess the answer is they were designed and built by real engineers and a substantial company before the negative interference of accountants and the cost shavings able to be modelled/tested by computers!

1991 BX19GTi Auto

-

docchevron

- The Immoderate half of the admin team

- Posts: 7524

- Joined: Sun Jun 04, 2006 7:03 pm

- Location: A Bucket of Fish

- x 7

RM's and RT's lived forever mainly because they went through Oldenham works every few years, and were completly rebuilt everytime.

There are virtually no RT's or RM's that have the same chassis number / reg they started with. LT had (and still have) exemption to move plates around at will, so it was not uncommon to see a RT going in one end of Oldenham and the very same leaving Oldenham having been rebuilt at the same time!They also dont have chassis's as such, they are built on subframes so each unit was easily replaced.

The Dennis Lance came about when no-one was buying full size single decks, by 1993 every operator in the land had fallen in love with midi buses, which is why the Dennis Dart was and is so popular.

The Dart is actually built on a reworked Dennis Dustcart chassis but is much simpler and less prone to rot.

The Lance was built in limited numbers and to a proce, they had to be to sell. What really killed them was Dennis's choice of chassis paint, which was plastic based grey shit, and only about 5 microns thick (to keep costs down).

It went brittle in about 3 minutes and allowed water and shit behind the paint, from where the cheapest steel known to man was free to rot away unnoticed until they fell apart.

I do agree with David though, welding bus chassis is heavy work (ie stripping it and dealing with lots of KG's of a steel in one go is fucking labour intensive) but actually welding big fuck off lumps of steel is on the whole a joy. Turn the wick up and plug away!

I just wish there was less to do!

But I'm not giving up, it's a little bit of history, not right now maybe, but in not many years it really will be the only one, so it's worth doing right.

That and I've hankered after this thing for 10 years, and it's spent it's whole life being abused (as much by me as anyone else, although I never crashed it!) so it deserves so time and money being lavished on it and having a decent retirement..

There are virtually no RT's or RM's that have the same chassis number / reg they started with. LT had (and still have) exemption to move plates around at will, so it was not uncommon to see a RT going in one end of Oldenham and the very same leaving Oldenham having been rebuilt at the same time!They also dont have chassis's as such, they are built on subframes so each unit was easily replaced.

The Dennis Lance came about when no-one was buying full size single decks, by 1993 every operator in the land had fallen in love with midi buses, which is why the Dennis Dart was and is so popular.

The Dart is actually built on a reworked Dennis Dustcart chassis but is much simpler and less prone to rot.

The Lance was built in limited numbers and to a proce, they had to be to sell. What really killed them was Dennis's choice of chassis paint, which was plastic based grey shit, and only about 5 microns thick (to keep costs down).

It went brittle in about 3 minutes and allowed water and shit behind the paint, from where the cheapest steel known to man was free to rot away unnoticed until they fell apart.

I do agree with David though, welding bus chassis is heavy work (ie stripping it and dealing with lots of KG's of a steel in one go is fucking labour intensive) but actually welding big fuck off lumps of steel is on the whole a joy. Turn the wick up and plug away!

I just wish there was less to do!

But I'm not giving up, it's a little bit of history, not right now maybe, but in not many years it really will be the only one, so it's worth doing right.

That and I've hankered after this thing for 10 years, and it's spent it's whole life being abused (as much by me as anyone else, although I never crashed it!) so it deserves so time and money being lavished on it and having a decent retirement..

Smokes lots, because enough's enough already!

Far too many BX's, a bus, an ambulance a few trucks, not enough time and never enough cash...

Far too many BX's, a bus, an ambulance a few trucks, not enough time and never enough cash...